Chilled Water Unit

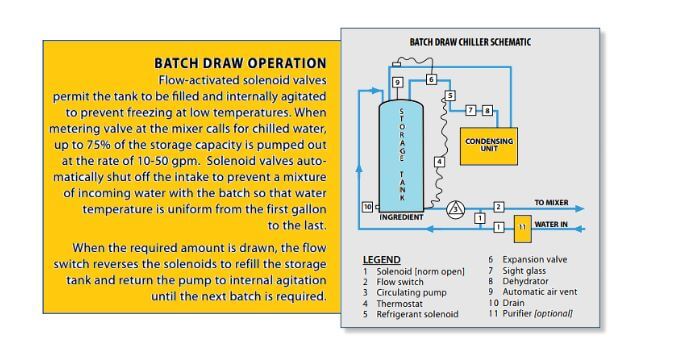

In Food Industry the important uniform batch temperature from first drop to last through their unique design principle and superior construction Chilled Water Unit have become standard throughout the industry for dependable uniformity in ingredient batch-draw water cooling. Unlike instantaneous chillers which are in constant danger of freeze-up at temperatures below 7°C, chillers are specially designed with high-transfer immersion coil evaporator and large holdover storage to supply ingredient water at 1°C and to maintain temperature setting within ± 8°C. This important storage feature not only provides a large volume of chilled water for dough; it also acts as a refrigeration “cushion,” preventing overload and “short cycling” common to chillers without storage.

OPERATION The Jacket Chiller is designed to operate continuously, circulating a water and glycol mixture between the chiller and mixer jacket to extract heat generated by high-speed mixing and maintain proper dough temperature during the mixing process. Temperature of water glycol solution circulating through the jacket is 5°C to 7°C as selected.

SAVE ENERGY AND SPACE For space-saving efficiency and economy the Ingredient and Jacket Water chillers can be combined into one unit. PB models can be paired with PCP units of balanced capacity to provide PBC models in one, compact housing. The combination Ingredient and Jacket Water chiller includes separate cooling circuits, each with its own compressor and individual controls. These circuits can be operated separately when needed. All combination chillers are constructed of the same heavy duty components as the individual Ingredient and Jacket chillers mounted in a cabinet of enamelled aluminium panels with stainless steel corner legs and top on a welded angle iron frame. Panels removable for access to all components.